Stone Crusher Diagram

stone crusher diagram

Stone Crusher Overview:

Mining crusher, crushing machinery in more than 50% of the content of the total high capacity row compound particles larger than three millimeters. Invention British Heng. The stone crusher is specifically refers to mining rock crusher. Crushing operations often the size of feeding and nesting granularity into the rough broken in pieces and crushing. Gravel equipment, jaw crusher, impact crusher, impact crusher, compound crusher, single-stage hammer crusher, vertical crusher, gyratory crusher, cone crusher several.

Jaw crusher Introdcution:

The jaw crusher is a normal stone crusher, the use of the two jaw plate material extrusion and bending role rough broken or broken in a variety of hardness materials broken machinery. The broken bodies of the fixed jaw plate and movable jaw plate, when the two jaw plate close to the material is broken when two jaw plates leave the material is less than the discharge opening at the bottom of the discharge. The crushing action is carried out intermittently. This crusher compared to the advantages of simple structure, reliable and hard materials can be broken is widely used in mineral processing, construction materials, silicate ceramics and other industrial sectors, and cone crusher, jaw crusher with less investment , finished piece of stone, low production costs. Compared with hammer crusher wear parts for a long time, high production efficiency, and post-investment.

The 1980s to twenty per hour crushing about 800 tons of material a large jaw crusher feed size reached 1800 mm. Common jaw crusher the elbows board and two of the single-bracket. Former moving jaw at work only to make a simple arc swing, it is also known as a simple swing jaw crusher; latter arc swing up and down movement, it is also known as complex swing jaw crusher. The jaw crusher is widely used in many sectors of mining, smelting, building material, highway, railway, water conservancy and stone industry and other various materials crushing compression strength not more than 320 MPa.

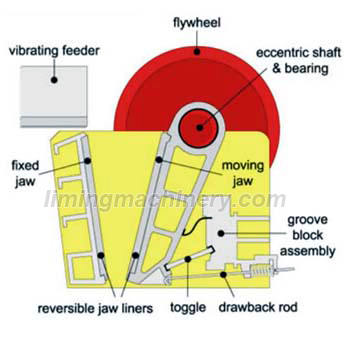

Jaw Crusher Working Principle:

Huge stones broken into small stones, the first crusher is often referred to as the "master" crusher. The longest history, the most solid crusher jaw crusher. Feeder jaw crusher (jaw crusher), containing material from the top of the entrance into the crushing chamber of the jaw teeth. Hubei tooth material top to the wall with great force, will be broken into smaller stones. Support the movement of the jaw teeth is an eccentric axis, this axis runs through the body architecture. Eccentric exercise is usually fixed at both ends of the shaft flywheel. Flywheel and eccentric support bearings are often used spherical roller bearings, bearing the working environment is extremely harsh. Bearings must withstand large impact loads, abrasive sewage and high temperature. Although this work environment is extremely harsh, jaw crusher still need to work very reliably, which is to ensure production efficiency.

Single broken elbow plate jaw up and down movement of the mobile jaw plate to promote nesting, and the upper level of stroke is greater than the lower part, easy broken chunk of material, so the crushing efficiency is higher than the elbows plate. The disadvantage is that the jaw plate wear faster, and the materials will be leaving the energy consumption increased crush phenomenon. Damaged in order to protect the important parts of the machine due to overloading, often simple shape, smaller size bracket designed to be the weak link, so that it occurs first in the overloading of the machine deformation or fracture. In addition, in order to meet the nesting size requirements and compensate for wear of the jaw plate, additional nesting population adjustment device, usually put in between the bracket seat and rear rack adjust shim or wedge. However, in order to avoid affecting production, the replacement of broken parts and hydraulics can be used to achieve insurance and adjustments. Some jaw crusher with hydraulic transmission to drive the movable jaw plate, in order to complete the crushing action of the materials. These two types of jaw crusher with hydraulic gear, often referred to as the hydraulic jaw crusher.

Liming Stone Crusher Diagram:

The stone crusher of Liming Heavy Industry is an excellent stone crusher. Liming Heavy Industry is committed to producing the best mining machinery and equipment, can produce various types of stone crusher. If you need a stone crusher or similar products, please contact us, we will provide quality service so that you get a satisfactory harvest.

Liming Heavy production of stone jaw crusher diagram as follows:

| Model | Max. Feeding Size (mm) | Adjustable Discharge opening (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimensions (mm) | Weight (t) |

| PE250×400 | 200 | 20-60 | 5-20 | 15 | 1150×1275×1240 | 2.8 |

| PE250x1000 | 210 | 15-50 | 15-50 | 30 | 2790x2670x1380 | 6.5 |

| PE400×600 | 350 | 40-100 | 15-60 | 30 | 1700×1732×1653 | 6.5 |

| PE500×750 | 425 | 50-100 | 50-100 | 55 | 2035×1921×2000 | 10.3 |

| PE600×900 | 500 | 65-160 | 60-130 | 75 | 2290×2206×2370 | 15.5 |

| PE750×1060 | 630 | 80-140 | 110-250 | 110 | 2620×2302×3110 | 26.7 |

| PE900×1200 | 750 | 100-200 | 160-380 | 130 | 3789×2826×3025 | 51 |

| PE1000×1200 | 850 | 200-300 | 315-550 | 130 | 3889×2826×3025 | 56 |

| PE1200×1500 | 1020 | 150-350 | 400-800 | 200 | 4200×3750×3820 | 88 |

Notice: Any change of Jaw Crushers technical data shall not be advised additionally.